Photovoltaic systems are considered safe—and with good reason. However, one danger is frequently underestimated: electric arcs that occur directly on the solar modules. These can cause fires that are tough to locate and difficult to fight. And this is exactly where AFCI technology comes into play: it detects arcs early on, thereby helping to minimize potential fire risks. Read this blog to find out how your photovoltaic system detects and prevents arc faults.

The safety of photovoltaic systems is ensured not only by strict standards that minimize electrical hazards such as short circuits or electric shocks, but also by protective devices that prevent damage in the event of lightning strikes or voltage peaks and ensure a safe shutdown in an emergency.

This results in the fire risk associated with photovoltaic systems being very low: In Germany—one of the largest photovoltaic markets in Europe with over 2 million installed systems—there have been 350 fires involving a PV system in the last 20 years. And the system itself was the actual cause of the fire in only 120 cases.

* Statistically speaking, this means that 99.994% of operational photovoltaic systems have not caused a fire. And conversely, just 0.006% of photovoltaic systems pose a “risk of fire” according to the statistics—that equates to 1 in 17,000 systems.

| *Fraunhofer ISE, “Recent Facts about Photovoltaics in Germany”, Frauenhofer ISE, Photovoltaic Modules and Power Plants Division, Freiburg, updated status 18/08/2025 |

Risk of fire posed by faulty installation

The most common causes of fire in photovoltaic systems include material fatigue and corrosion, but the primary reason is faulty installation: serial arcs caused by loose contacts, poorly crimped (i.e., mechanically compressed) plugs, damaged cables, or incompatible plug connections are particularly dangerous. If, for example, MC4 plug connections from different manufacturers are installed in a photovoltaic system, they differ not only in terms of materials, but also when it comes to degradation and thermal expansion, which can result in a temperature increase of up to 97 °C at the contact points.

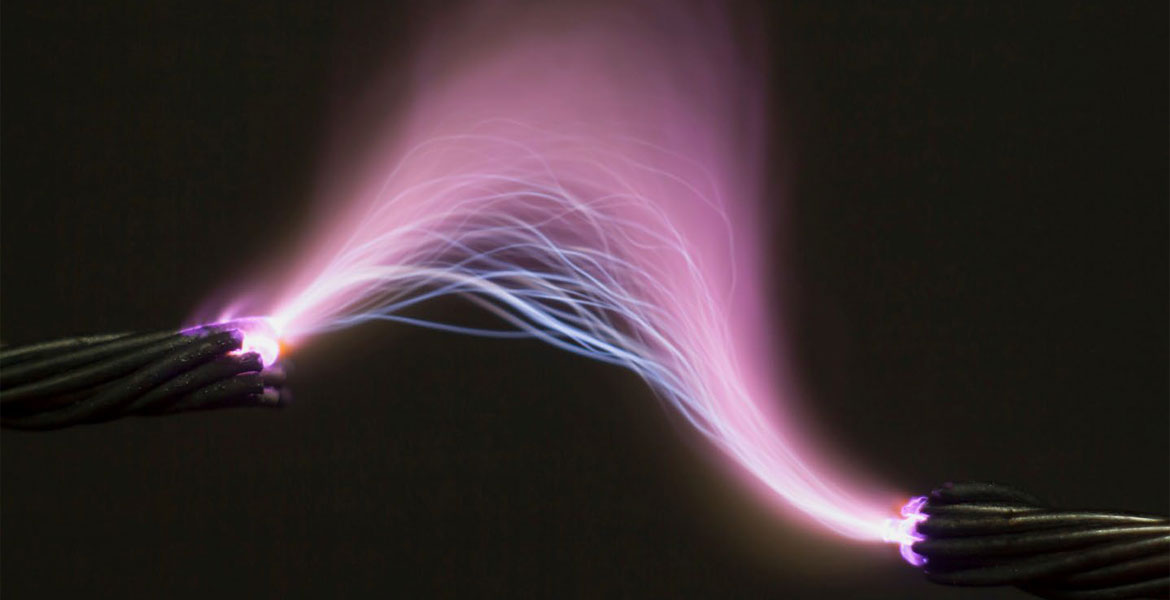

The upshot? Arcs that can reach temperatures of over 1,000 °C; enough to ignite surrounding material and cause damage that is sometimes not covered by insurance. The independent international standards organization (IEC) therefore stipulates the use of plug components from the same manufacturer.

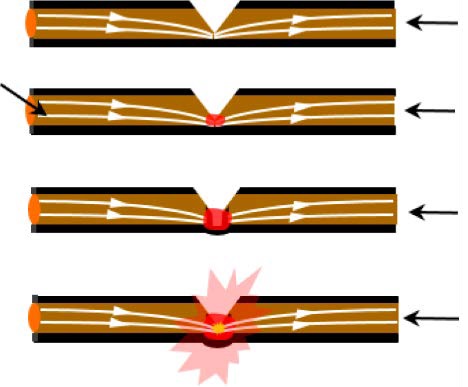

Arcing process in a conductor:

1. Reduction in the conductor cross-section

2. Higher contact resistance → increased heat generation at the contact point

3. Higher temperature accelerates the deterioration process → further reduction in cross-section and increase in contact resistance (loop between steps 2 and 3)

4. At a certain point, the continuity of the conductor is interrupted

DC optimizers: too much of a good thing?

DC optimizers are often installed in photovoltaic systems for power optimization at module level. In terms of fire protection, these offer the (supposed) advantage that they can switch off PV modules in an emergency. But it’s important to be aware that photovoltaic systems work with direct current and cannot simply be switched off because they generate electricity as long as light falls on the PV modules. If modern photovoltaic systems meet the rapid shutdown requirements, the optimizers can minimize the voltage at the PV module to a safe level in the event of a fire (e.g., below 30 V or even 1 V per module). This makes it easier for firefighters to extinguish the fire safely and reduces the risk of electric shock, although the modules are not completely disconnected from the circuit.

Unfortunately, the use of power electronics on each individual PV module is accompanied by a high number of DC connections in the photovoltaic system: compared to a photovoltaic system without power optimizers, a system with power optimizers requires around three times as many plug connections on the modules, which in turn increases the probability of electric arcs and the risk of fire. Furthermore, DC power optimizers—like most photovoltaic components—are designed for an ambient temperature of 60 degrees Celsius. In the event of an actual fire, it is therefore very likely that the DC optimizers would quickly start to melt or smolder instead of safely shutting down the module output.

Don’t cut costs in the wrong areas

Thinking of saving money by using incompatible plugs or combination pliers instead of special tools? Buying a photovoltaic system can certainly be expensive, so it may be tempting to opt for an amateur electrician among your friends or acquaintances when performing some installation work to keep costs down. However, cutting corners here is well worth avoiding—because you can only be sure that the system has been connected in accordance with all safety standards if you ask a professional to take care of the work.

This is precisely what makes the difference: photovoltaic systems do not pose a higher fire risk than any other electrical systems, but the relevant rules for electrical safety must be observed. And this applies both to the system components and the installation process itself. In the long run, it pays to focus on quality and professionalism.

What to look out for during installation:

- What to look out for during installation

- Careful and professional execution (correct crimping, secure cable routing)

- Compliance with the prescribed construction measures (fire protection standards, grounding)

- Simplicity of the system and minimum number of DC plugs

- Regular inspection and, if necessary, maintenance of the PV system

Arc Fault Circuit Interrupters (AFCI): how does arc detection work in a photovoltaic system?

AFCI (Arc Fault Circuit Interrupter) systems detect dangerous serial arcs by continuously analyzing electrical signals in the DC circuit. The technology checks the current signal for typical patterns that indicate an arc. These include changes in the frequency spectrum of the current, pulse-like current peaks, current flows even when the voltage is interrupted, irregular noise, and repeated fault conditions within a short period of time.

An AFCI therefore permanently monitors the current and voltage curves in the DC circuit of the photovoltaic system and records both low-frequency and high-frequency signal components. Digital signal processing and an intelligent, adaptive algorithm are used to analyze and evaluate the recorded signals with the aim of reliably detecting real electric arcs, while also avoiding false alarms. As soon as the system recognizes a pattern that can be clearly assigned to a dangerous arc, the affected circuit is disconnected within milliseconds. This stops the energy supply to the arc and prevents a fire before it can start.

Susceptibility to interference from ambient noise

AFCI systems are highly sensitive to external interference factors, which also poses the biggest challenge: electromagnetic interference (EMI) from neighboring devices, switching operations or atmospheric influences (e.g., lightning strikes) can generate signal patterns similar to arcs. If these are incorrectly assigned by the AFCI, this can lead to false tripping resulting in the photovoltaic system switching off unnecessarily and the associated yield losses. Sophisticated technology like the Fronius Arc Guard resolves this issue.

Fronius Arc Guard: safety included

Specially developed for photovoltaic systems, the arc fault circuit interrupter Fronius Arc Guard is pre-integrated directly into Fronius inverters—in terms of both software and hardware. Its activation is simple and straightforward via the user interface of the inverter, which means that the photovoltaic system does not require additional components such as switch boxes or other connection points. It also saves further installation work.

The extensive knowledge and many years of experience gained by Fronius in the field of arc welding have been incorporated into the development of the intelligent arc fault protection device. The outcome is an efficient technology built on FFT-based spectral arc detection: a mathematical method (Fast Fourier Transform) with which a time signal (e.g., current or voltage) is broken down into its frequency components from which the current curve and any interference—as previously described—are analyzed. Innovative pattern recognition techniques and a trained arc detection algorithm facilitate the continuous improvement of the Fronius Arc Guard, as well as the constant increase in detection accuracy.

Safer with the principle of precaution. The Fronius Arc Guard operates according to the principle of precaution—it detects and extinguishes arcs before they can lead to a fire. If an arcing event is detected, the power stages of the inverter interrupt the power transmission and stop feeding power into the grid. This interrupts the current flow and extinguishes the arc. While special standards for AFCI systems in PV systems have been in force in the USA since 2018, there are currently no standard requirements at EU level. The Fronius Arc Guard satisfies international safety standards for arc detection such as UL 1699B and IEC 63027, making it future-proof for global markets.

Did you know?

The powerful Fronius Verto inverter for agriculture, small businesses and larger detached homes and multi-occupancy dwellings is equipped with automatic arc detection (AFCI) as standard. Potential arcs are quickly identified and extinguished, enhancing both safety and efficiency.

Conclusion:

Photovoltaic systems are not a fire hazard, but fault arcs—for example due to damaged plug connections or improper installation—can still pose a risk. The integration of AFCI technology like the Fronius Arc Guard offers a targeted solution here: it detects critical patterns in the current flow and interrupts the circuit before a fire can actually start. An AFCI is not a sign of insufficient safety, it is an intelligent form of added protection that further strengthens the already high safety level of photovoltaic systems.

For further information on fire safety and arc detection in photovoltaic systems, read our whitepaper and watch the Fronius Business Academy webinar.