They often go completely unnoticed, yet we rely on them every single day. From cars and bridges to power stations and railings, welded seams are what hold our world together. Yet to do this reliably, every welded construction needs to establish a stable connection. Our practical overview explains everything you need to know about the different types of welding joints and seams. We also tell you how to produce clean seams every time with Fronius Velo.

What types of welding joints are there?

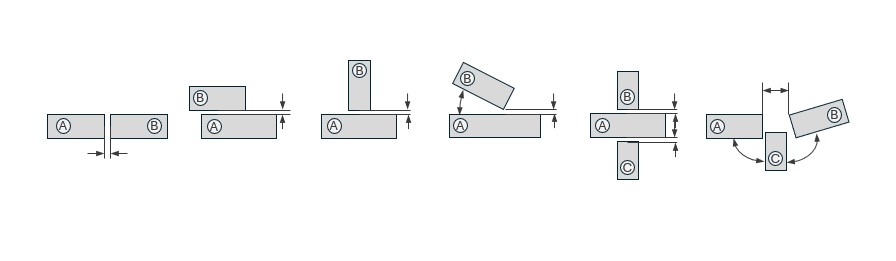

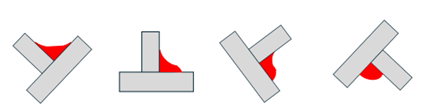

The way in which two sheets or components are connected to each other is described by the “joint type”. A distinction is made between butt joints, lap joints, T-joints, cruciform joints, angle joints, and multiple joints. The corner joint is a special case of an angle joint where two metal plates are joined at a 90° angle to each other.

What types of weld seams are there?

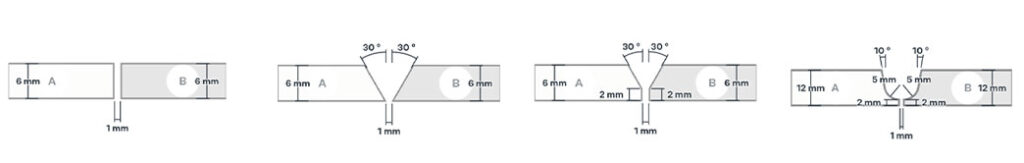

We generally differentiate between single-sided and double-sided seams. Single-sided seams include square butt welds, single-V butt welds, Y-butt welds, and single-U butt welds. If the edges are prepared on one side, they are called single-bevel butt welds, single bevel tee-butt welds, and single-J butt welds. If we weld from the top and the underside, a “D” for “double” is added to the seam designation (for example DV or DHV).

The flange weld and the square edge weld are special cases of the square butt weld, where the former is completely or partially leveled off after welding and enables the highest welding speeds.

Weld Seam thickness

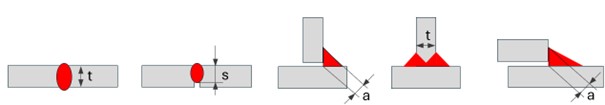

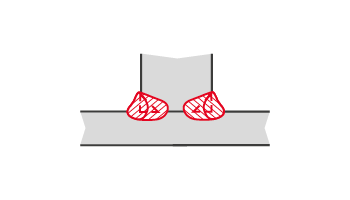

An important concept in this context is the seam thickness, because it determines the load-bearing cross-section of the weld seam. Depending on the sheet thickness and required strength of the component, a full or partial penetration weld is produced.

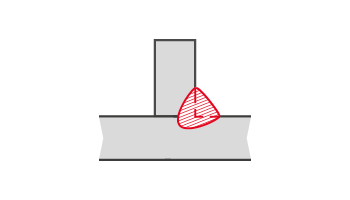

If the seam covers the full material thickness of the sheet, the sheet thickness is designated as “t”, otherwise the thickness is marked with an “s”. For fillet welds, the smallest right-angled triangle under 45° is the load-bearing cross-section, which is referred to as the “a dimension”.

Welding positions

The welding position is also crucial for the edge preparation and producing a flawless joint. In the flat position (PA), the weld pool usually runs out evenly, which is no longer the case in the horizontal position (PB) at high deposition rates.

The transverse seam (PC) has the advantage of supporting the lower half of the sheet. In the case of vertical-up (PF) or overhead (PE) seams, the deposition rate must be significantly reduced because there is virtually no support effect.

Overview of the most important weld seams

| Identification | Description | Seam representation | Symbol |

| Fillet weld | The single-pass fillet weld is used for T and lap joints without special edge preparation. The decisive factor is the reliable detection of the root point, to which a small air gap and a short arc length contribute. |  |  |

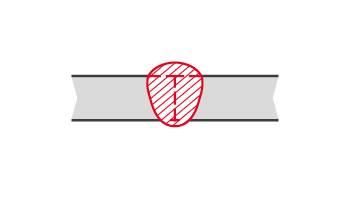

| Square butt weld | When two sheets with straight flanks are butted together, a square butt weld is created. |  |  |

| Single-V butt weld | Preparing sheet edges on both sides for a butt weld reduces the risk of a lack of fusion and allows the weld pool volume to be adjusted depending on the opening angle. |  |  |

| Y-butt weld | A Y-butt weld is created when a root face remains where two prepared components meet. How high this face is and whether there is an air gap between the components determines whether the seam can be fully welded through from one side or whether the risk of root fusion defects is too high. |  |  |

| Double-V weld | Preparing the edge on both sides is particularly advantageous for thicker sheets, as it significantly reduces the volume of the weld pool. The side that is easier to access should be ground down by about two thirds of the sheet thickness. This 2/3 rule of thumb has proven itself in practice. |  |  |

| Double-bevel butt weld | Preparing only one side of the sheet or component is very often used in combination with thick sheets where fillet welds will be applied. This double-bevel edge preparation is applied when welding on dividers or thick tabs. |  |  |

| Double-HY weld | Despite the weld seam on both sides, a full penetration weld is not usually required. This application is reserved for very thick sheets, even without a defined air gap. |  |  |

Free download

Download our poster showing all the relevant weld seam profiles in a compact, free, and structured format. For on the go there’s our WeldConnect app, which allows you to conveniently calculate deposition rate and welding parameters.

Our insider tip for perfect weld seams every time!

Concentration and a steady hand are essential in manual MIG/MAG welding. However it can be a real challenge to keep a steady motion, especially with long seams.

Over time, small deviations creep in and the seam quality suffers. In addition the task quickly becomes very physically demanding, even for experienced welders.

Velo, the Velocity Assistant from Fronius, provides clever support for manual welding. The system actively guides the torch while also keeping the speed constant.

At its heart is the so-called Velo wire, which touches the workpiece and generates a forward movement through friction. As a cold wire, it operates completely without an arc.

For Velo to work you need either a root edge (for fillet welds), the transition area between two overlapping beads (for multi-pass seams), or the joint edge of the sheets (for butt welds).

This keeps your welding torch at the optimal distance at all times for precise and even results with every seam. Find out more about Fronius Velo now!

Want to know more?

From innovative technologies to unusual locations, many more exciting insights into the world of welding await you in our blog. Explore our collection of posts and discover articles on LaserHybrid and welding in the wild!