What does “TIG” stand for? Why is inert gas used in this process? And what role do tungsten electrodes play? Welding is complex but the basics are actually pretty easy to understand. The Fronius “What is …?” series helps to build an understanding of welding and to maintain an overview of the basic terms.

Tungsten Inert Gas Welding

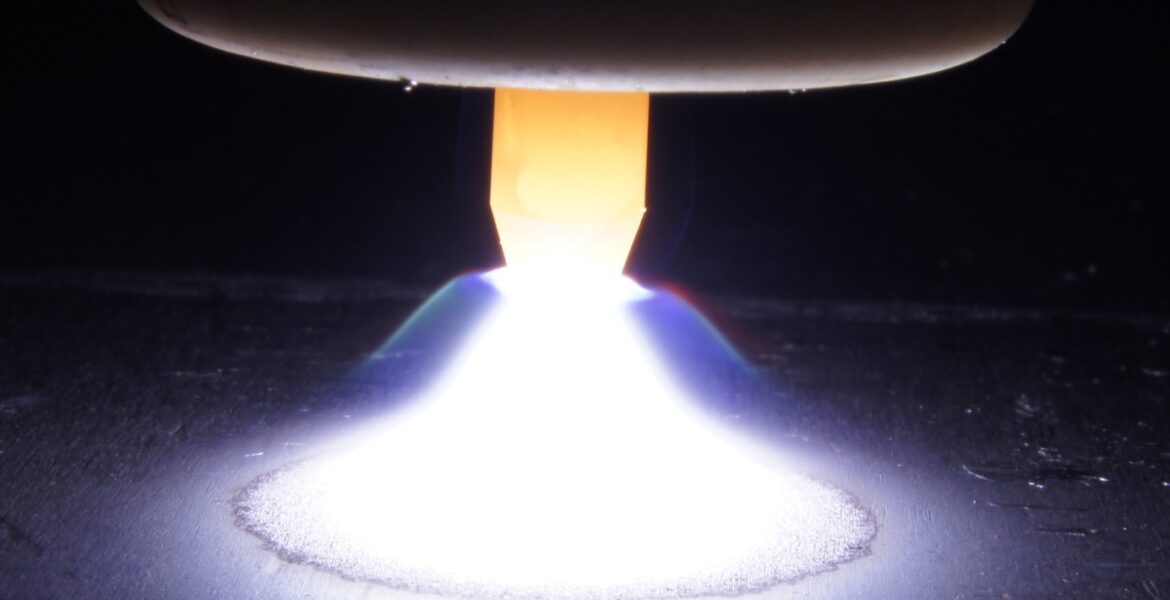

TIG welding is a process that enables top-quality weld seams. The arc burns between a temperature-resistant, non-melting tungsten electrode, and the workpiece. The inert shielding gas that gives the process its name creates an oxygen-free gas atmosphere and prevents chemical reactions with the liquid weld pool. This results in smooth, level, and non-porous weld seams. The filler metal is guided manually or using a wirefeeder.

TIG welding can be used for all metals that are suitable for welding. The biggest area of application here is stainless steels, and the processing of non-ferrous metals such as aluminum, copper, and brass. TIG is primarily used for root passes as the seams are smooth and non-porous, and can therefore withstand dynamic forces well.

Inert Shielding Gas

For TIG welding, reaction-free (inert) shielding gas is used. The gas atmosphere has a protective function, preventing chemical reactions with the liquid weld pool and the heated material. This guarantees high-quality weld seams.

The noble gases argon and helium, or a mixture of these gases, are used as shielding gases. Argon is used most frequently as it provides optimal conditions for ignition and ensures a particularly stable arc. Helium conducts heat more efficiently than argon and therefore ensures deep and wide penetration.

Tungsten Electrodes

The tungsten electrode is at the core of TIG welding. At 3380 degrees Celsius, tungsten has the highest melting point of any pure metal in the periodic table. This means the electrode can emit an arc that heats and liquefies the workpiece without itself melting away.

The electrodes are produced using a sintering process. They can also be alloyed using oxidic additives to improve their properties. The electrodes are color-coded according to the alloy used:

Tungsten/lanthanum oxide electrodes are colored blue

- Pure tungsten (WP) (green):

Flat, spherical electrode surface

Ignition problems with DC

Low current-carrying capacity - Thorium oxide (WT 20) (red):

Excellent ignition properties

Significantly higher current-carrying capacity than pure tungsten electrodes

Slightly radioactive (alpha emitters) - Cerium oxide (WC 20) (gray):

Similar properties to thorium

Non-radioactive - Lanthanum oxide (WL 20) (blue):

Longer service life than tungsten/thorium or tungsten/cerium oxide electrodes

Poorer ignition properties

High Frequency Ignition

One particular characteristic of TIG is that the arc can be ignited without contact. A series of fast high-voltage pulses cause a spark to jump across to the workpiece and the arc then stabilizes itself. High frequency ignition is extremely easy for the welder to handle. The electrode cannot stick to the workpiece, is not contaminated, and no tungsten inclusions are created in the seam.

You can read more about the advantages of the TIG process in the Fronius blog article “TIG Welding: Top-Quality Connections.”